Industrial engineering, manufacturing and mechanical supply partner with over 20 years of industry experience supporting factories across the UAE.

Al Muharik Engineering LLC is a UAE-based industrial engineering company providing a combination of precision manufacturing capabilities and reliable mechanical component supply. We support maintenance, production and engineering teams with both standard items and customised solutions.

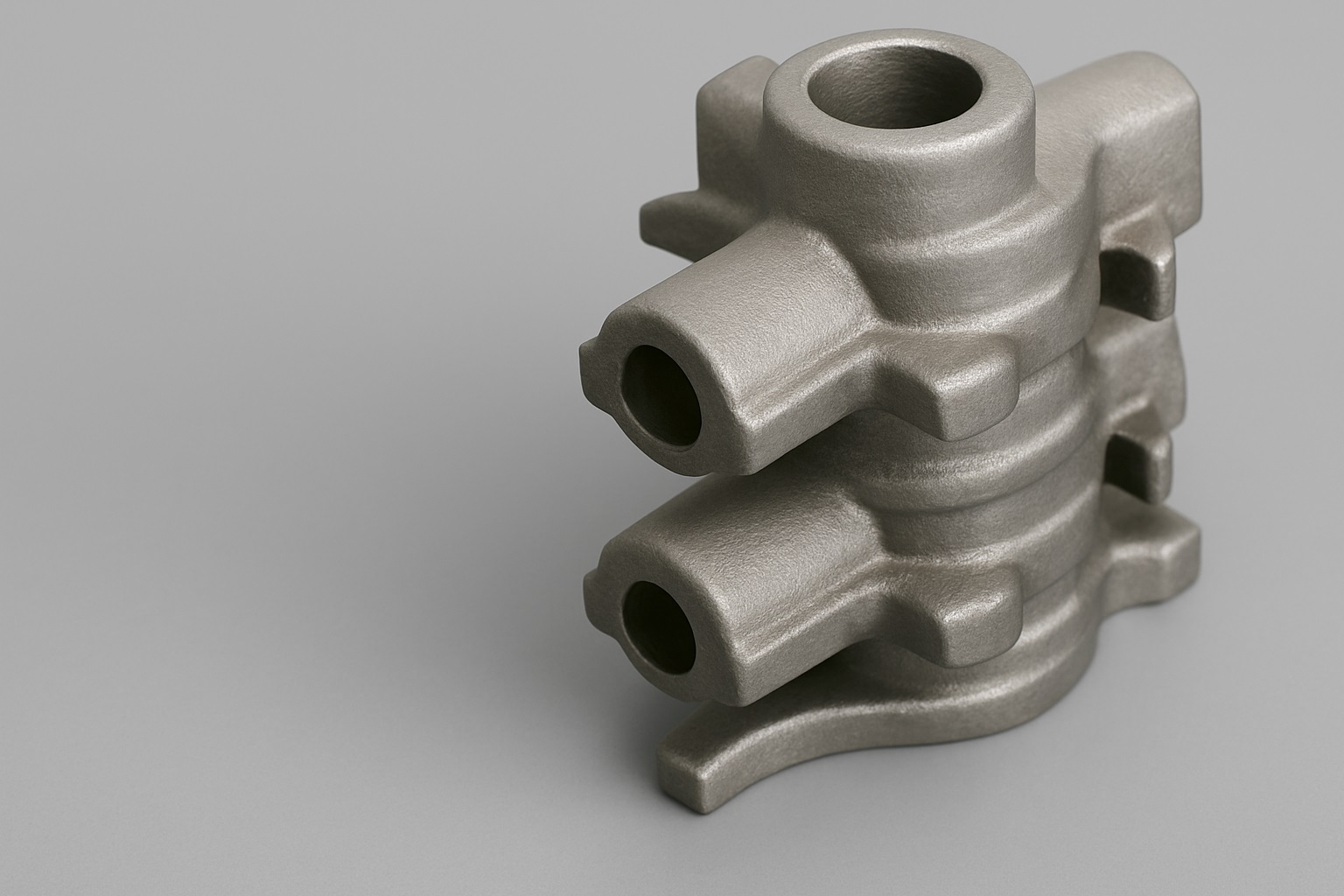

Our services include machining and milling works, CNC machining, CNC wire cutting, laser cutting of plates and pipes, industrial gear manufacturing, sectional steel fabrication, hydraulic works, metal casting (Aluminum, Cast Iron, Bronze and other alloys), heat treatment and hardening, chrome plating, and industrial blade sharpening.

In parallel, we supply essential mechanical and industrial components including bearings, shafts, motors, pumps, valves, fasteners, seals and gaskets, industrial springs, rubber components and related spare parts.

With over two decades of hands-on industry experience, we understand the realities of factory operations — unplanned downtime, urgent breakdowns, and the importance of sourcing the right component first time. Our role is to help you identify suitable specifications, recommend reliable options and alternatives, and deliver within the timelines your operation requires.

Whether supporting preventive maintenance programs or urgent corrective works, our focus is on practicality, responsiveness and long-term partnership.

We have supported manufacturing and industrial clients across multiple sectors including perfumes, food and beverage, hygiene products, flexible and rigid packaging, dairy, paper, metal cans and industrial services.

Over the years, we have worked with organisations such as Rasasi Perfumes, Kolson Food, Fine Hygienic Papers, Falconpack, Al Bayader, Hotpack, Marmum Dairy Farm, Tayseer Arar, AAL Group, Arabian Can Industries, Arabian Packaging, Technoman Group and Metropolic Paper Industries.

Our approach is built around long-term relationships — understanding your installed equipment, mapping critical components, and being prepared with options when you need them. This reduces supplier fragmentation and helps simplify industrial sourcing through a single, technically aware point of contact.